Application: Hot and cold drinking water, gen. pressure pipes

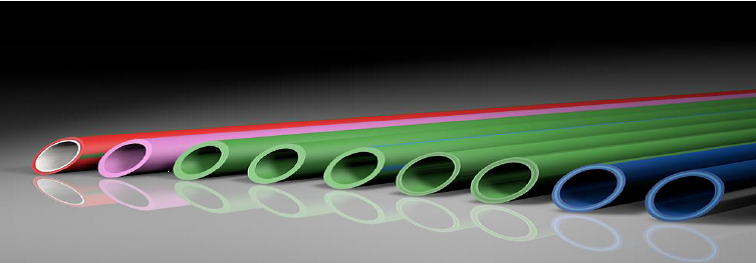

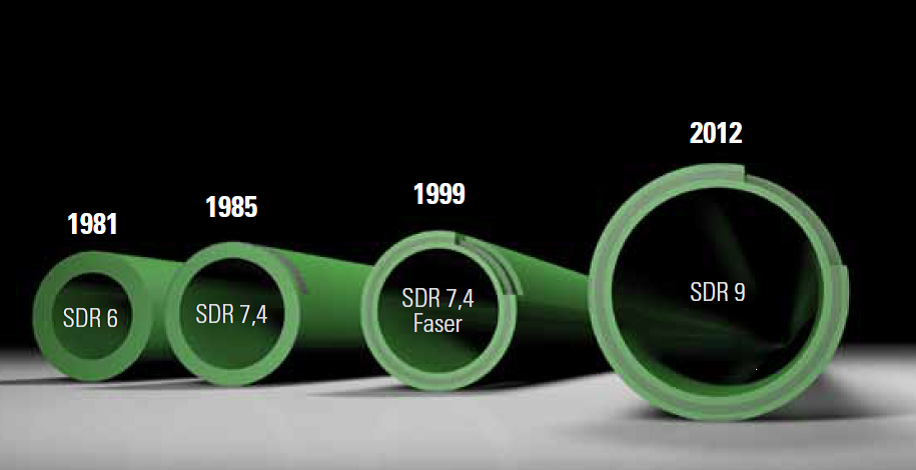

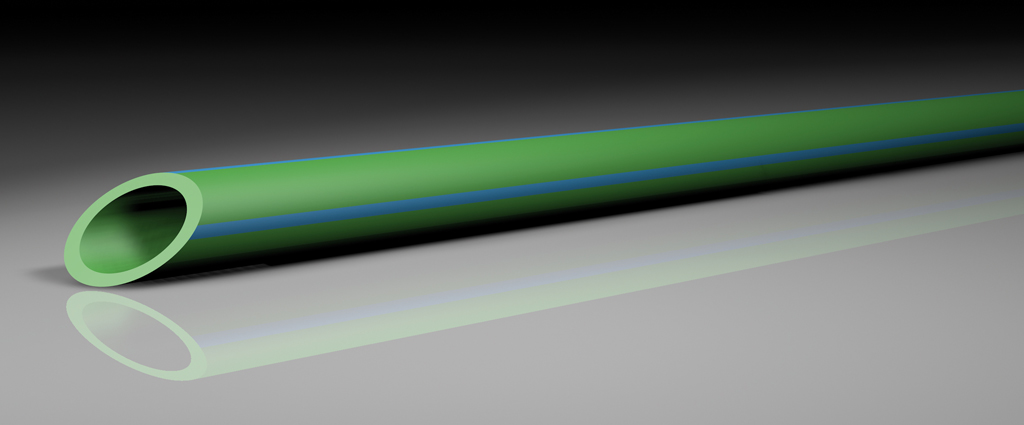

Pipe series: aquatherm green pipe MF (Multilayer Fibre) SDR7.4

Download general information aquatherm green pipe MF SDR7.4

Pipe series: aquatherm green pipe MF RP (Multilayer Fibre Raised Pressure) SDR9

Download general information aquatherm green pipe MF RP SDR9

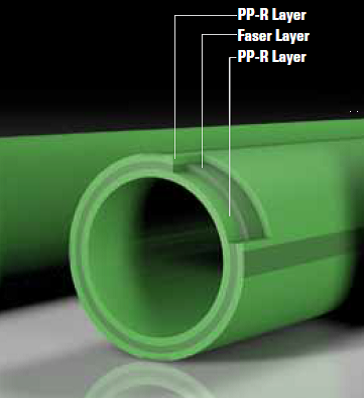

Material: fusiolen PP-R fibre reinforced (faser composite technology)

Standards: Watermark Certificate of Conformity Level 1

Certificate No.: WMKA02437

Colour: green with 4 dark-green stripes

Form supplied: 4m straight lengths Ø 20 – 125 mm), 5.8 m straight lengths (Ø 160-355mm)

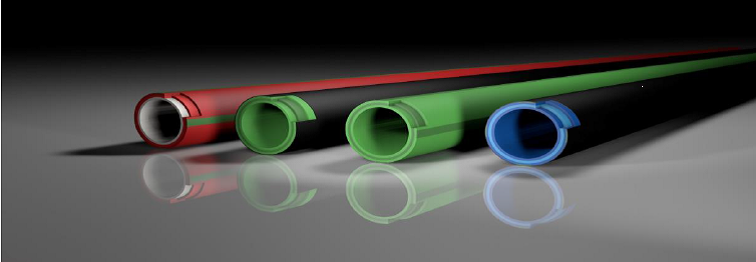

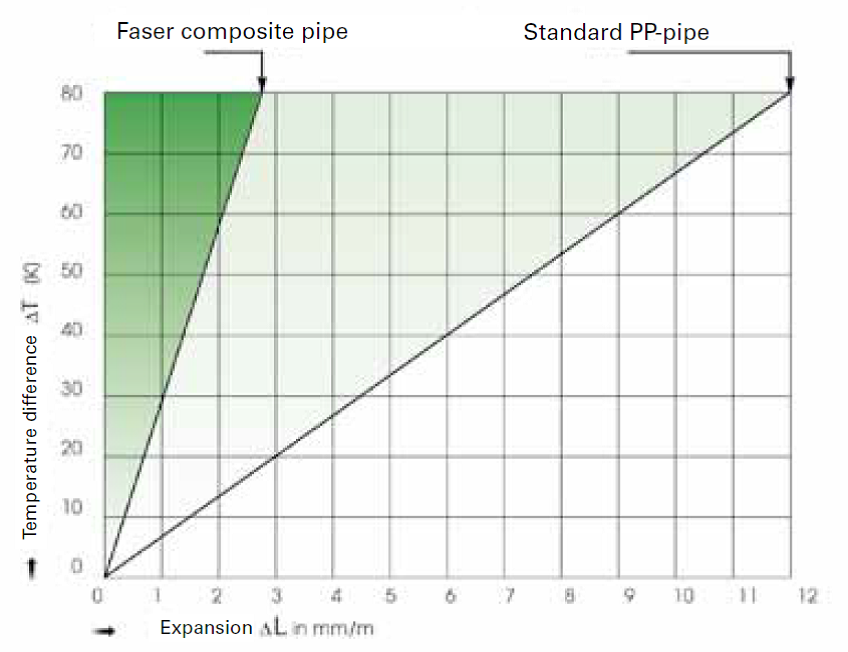

Mechanically stabilized through a fibre mix integrated in the middle layer of the fusiolen® PP-R

Identification: 4 moss – green stripes

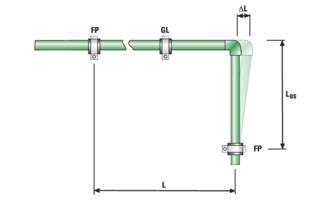

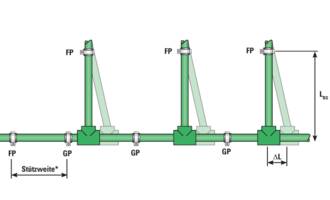

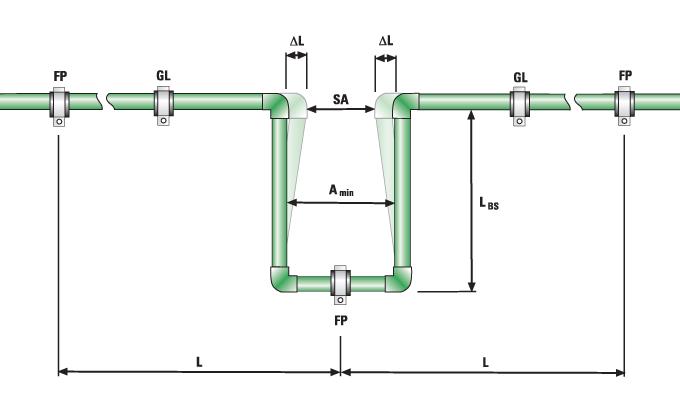

Provision for expansion aquatherm MF pipe vs Copper pipe

Cautionary Note mixed PP-R/Copper Hot Potable Water Reticulation System (only)

Building Water Services Seminar 2018

Standards Australia Statement AS/NZS3500.4 Plumbing and Drainage

Hydraulic Services Design Guide ICAA April 2014

AS3500.4:2015 vs Hydraulic Services Design Guide ICAA

Australian HWRS velocities in Copper pipes over the years (2003 - 2018)

Flow induced failure mechanisms of Copper pipe

Copper erosion corrosion report

IPA Statement Issue 2015-1 AS3500.4

IPA Report Copper Velocity and Temperature in HWRS

IPA Statement Issue December 2017 AS3500.4

IPA Statement Issue September 2018 AS3500.4

Chlorine dioxide as disinfectant warning

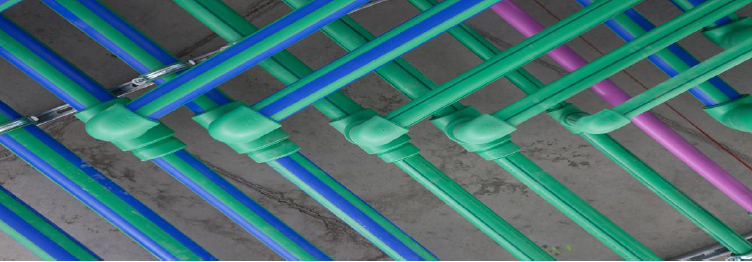

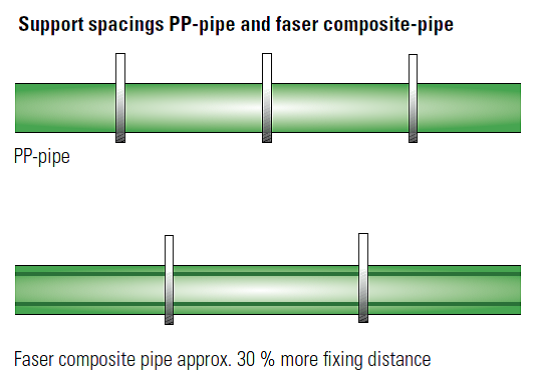

Please only use the aquatherm proprietary pipe clamps!

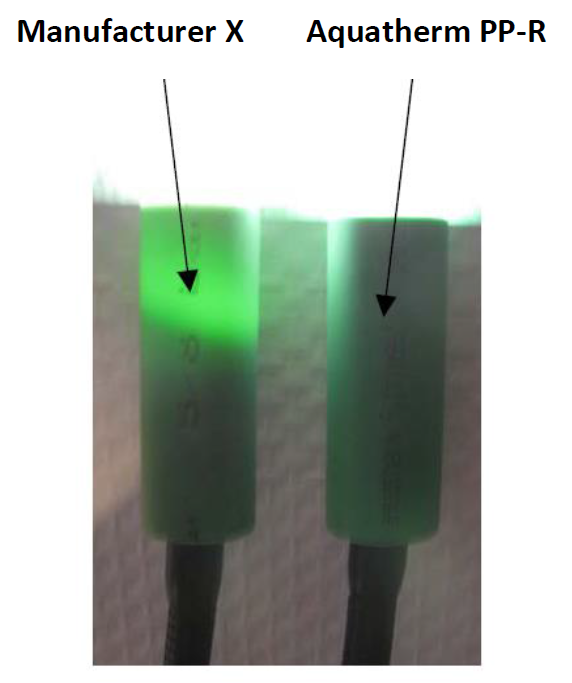

Various national and international independent authorities and institutions confirm aquatherm's quality standard

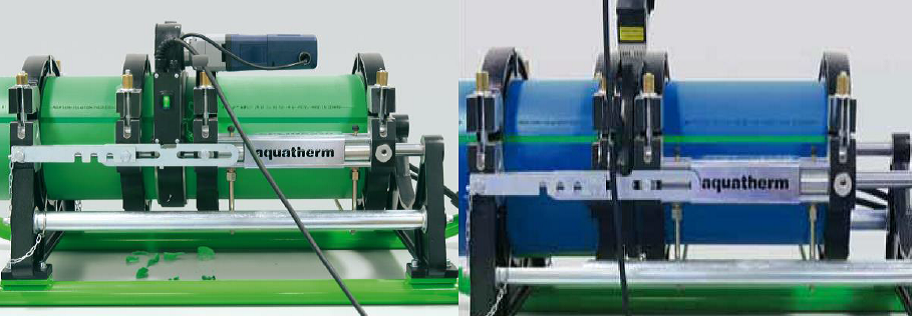

Welding procedures videos:

![]()

20-63mm: Socket Fusion

50-125mm: Socket Fusion

160mm and up: Butt welding

20-250mm: Electrofusion

Please also refer to chapter "Training / Processing Welding Videos"

Available dimensions (* = SDR7.4):

|

Art-No. |

Dimension |

DN |

|

70708* |

20 x 2.8 mm |

15 |

|

70710* |

25 x 3.5 mm |

20 |

|

370712 |

32 x 3.6 mm |

25 |

|

370714 |

40 x 4.5 mm |

32 |

|

370716 |

50 x 5.6 mm |

40 |

|

370718 |

63 x 7.1 mm |

50 |

|

370720 |

75 x 8.4 mm |

- |

|

370722 |

90 x 10.1 mm |

65 |

|

370724 |

110 x 12.3 mm |

80 |

|

370726 |

125 x 14.0 mm |

100 |

|

370730 |

160 x 17.9 mm |

125 |

|

370734 |

200 x 22.4 mm |

150 |

|

370738 |

250 x 27.9 mm |

200 |

|

370742 |

315 x 35.2 mm |

250 |

|

370744 |

355 x 39.7 mm |

- |

Application: Cold drinking water and rain water, gen. pressure pipes

Pipe series: aquatherm green pipe SDR11

Download general information aquatherm green pipe SDR11

Material: fusiolen PP‐R

Standards: Watermark Certificate of Conformity Level 1

Certificate No.: WMKA02437

Colour: green with 4 blue stripes

Form supplied: 4 m straight lengths (Ø20 ‐ 125mm).

5.8 m straight lengths (Ø160 – 450mm)

Ø20 ‐ 32mm can be supplied in coils; on request

Chlorine dioxide as disinfectant warning

Please only use the aquatherm proprietary pipe clamps!

Welding procedures videos:

![]()

20-63mm: Socket Fusion

50-125mm: Socket Fusion

160mm and up: Butt welding

20-250mm: Electrofusion

Please also refer to chapter "Training / Processing Welding Videos"

Available dimensions:

|

Art-No. |

Dimension |

DN |

|

10208 |

20 x 1.9 mm |

15 |

|

10210 |

25 x 2.3 mm |

20 |

|

10212 |

32 x 2.9 mm |

25 |

|

10214 |

40 x 3.7 mm |

32 |

|

10216 |

50 x 4.6 mm |

40 |

|

10218 |

63 x 5.8 mm |

50 |

|

10220 |

75 x 6.8 mm |

65 |

|

10222 |

90 x 8.2 mm |

80 |

|

10224 |

110 x 10.0 mm |

80 |

|

10226 |

125 x 11.4 mm |

100 |

|

10230 |

160 x 14.6 mm |

125 |

|

10234 |

200 x 18.2 mm |

150 |

|

10238 |

250 x 22.7 mm |

200 |

|

10242 |

315 x 28.6 mm |

250 |

|

10244 |

355 x 32.2 mm |

300 |

|

10246 |

400 x 36.3 mm |

300 |

|

10248 |

450 x 40.9 mm |

400 |

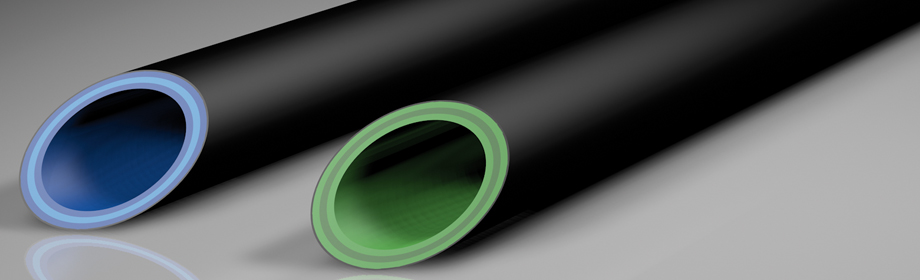

UV Resistance

Pipes and fittings made from fusiolen PP-R or fusiolen PP-R C are normally not installed where subject to UV-radiation.

All aquatherm PP-R pipes and fittings have UV stabilizer to bridge transport and installation times. Maximum storage time in the open air is 3 months under Australian UV-conditions.

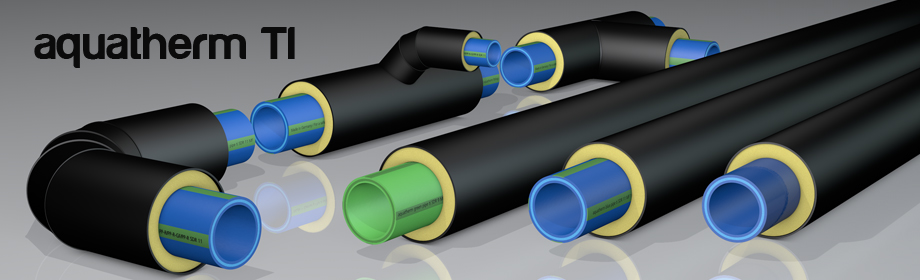

For the application in open air aquatherm offers composite pipes with an UV-protective layer made from black polyethylene, which excludes damages caused by sunlight.

Aquatherm PP-R fittings have to be protected against sunlight by using a black UV-resistant adhesive tape.

Painting the aquatherm PP-R pipes and fittings with an UV resistant epoxy based primer or lagging the aquatherm PP-R pipes and fittings with an UV resistant insulation is sufficient as well to protect the PP-R pipe system from UV damage.

Available types of pipe:

- aquatherm green pipe MF UV

- aquatherm blue pipe MF UV (on demand)

- aquatherm blue pipe MF UV-OT (on demand)

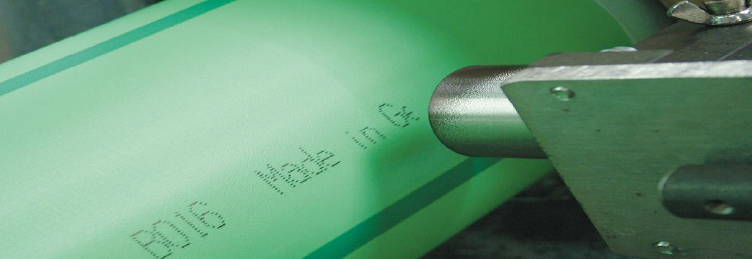

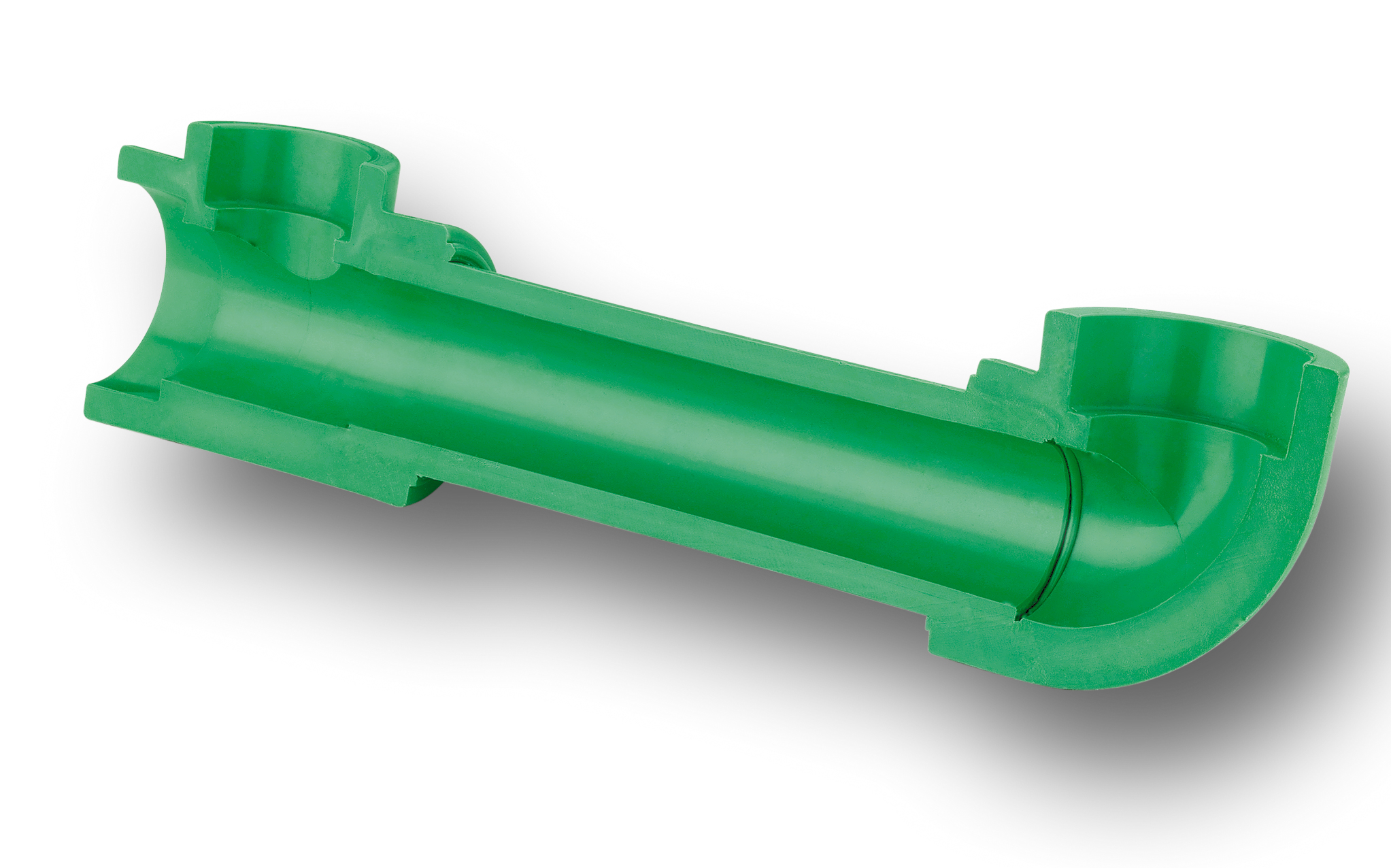

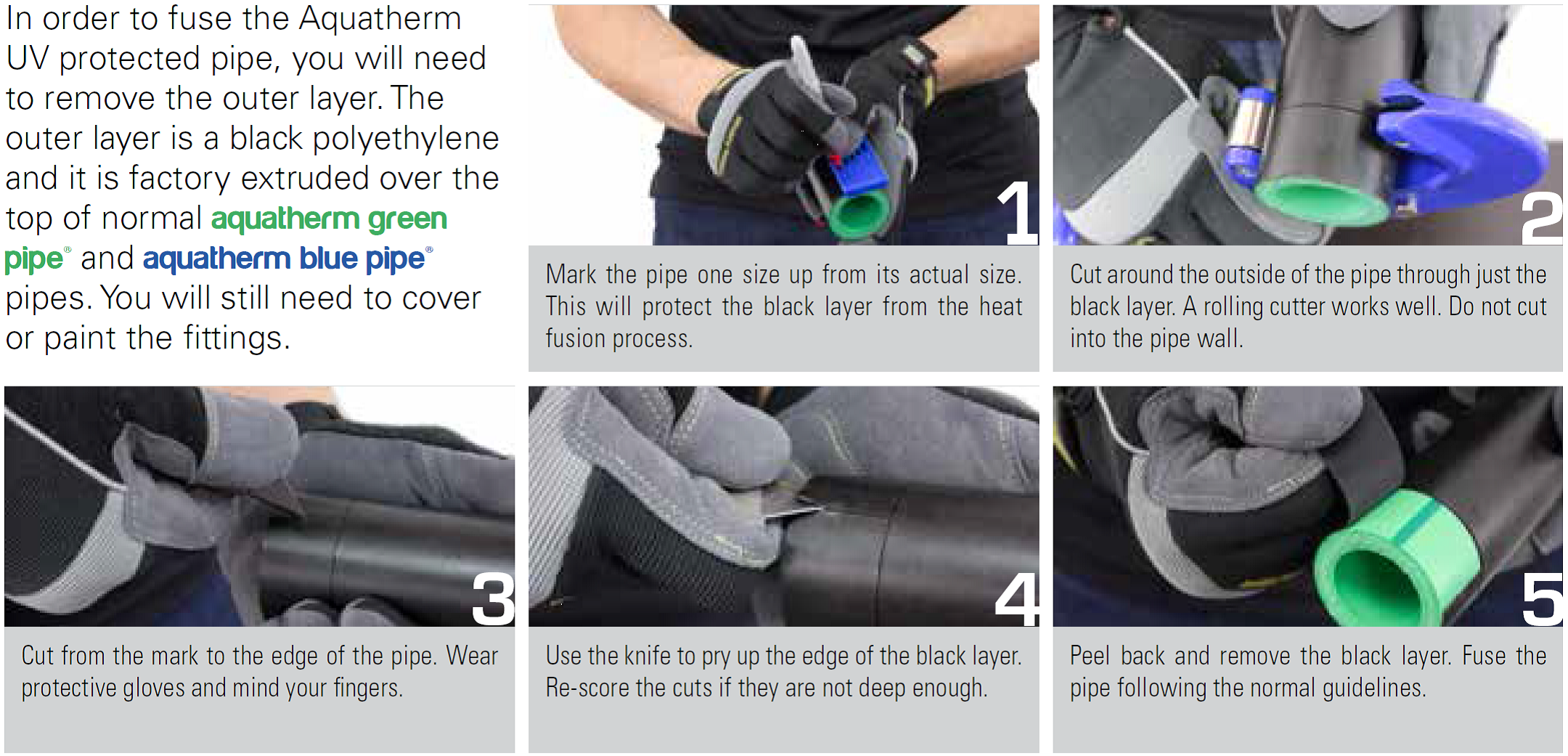

Peeling of the UV layer

When welding UV pipe peel off the UV layer off the aquatherm pipe before fusion.

Push the end of the UV pipe into the guide of the peeling tool. Peel off the UV layer up to the top of the peeling tool. It is not necessary to mark the welding depth as the back stop of the peeling tool indicates the correct welding depth.

Before starting the fusion, check if the UV layer has been completely removed.

Peeling of the UV layer (option 1)

Click here for more information on the pipe peelers for the UV pipe

Peeling of the UV layer (option 2):

NEW: Aquatherm offers new solution for painting the aquatherm PP-R pipe systems

Click on below picture to download Technews No.14 2015

Application: Hot and cold drinking water (outdoors), gen. pressure pipes

Pipe series: aquatherm green pipe MF (faser composite) SDR7.4 U.V.

Download general information aquatherm green pipe MF SDR7.4 UV

Material: fusiolen PP-R fibre reinforced with UV protection layer (faser composite technology)

Colour: outer layer: black

Inner layer: green

Form supplied: 4 m straight lengths (Ø20 ‐ 125mm).

5.8 m straight lengths (Ø160 – 250mm)

Mechanically stabilized through a faser mix integrated in the middle layer of the fusiolen® PP-R

Identification: Inliner green, outside black

Cautionary Note mixed PP-R/Copper Hot Potable Water Reticulation System (only)

Building Water Services Seminar 2018

Standards Australia Statement AS/NZS3500.4 Plumbing and Drainage

Hydraulic Services Design Guide ICAA April 2014

AS3500.4:2015 vs Hydraulic Services Design Guide ICAA

Australian HWRS velocities in Copper pipes over the years (2003 - 2018)

Flow induced failure mechanisms of Copper pipe

Copper erosion corrosion report

IPA Statement Issue 2015-1 AS3500.4

IPA Report Copper Velocity and Temperature in HWRS

IPA Statement Issue December 2017 AS3500.4

IPA Statement Issue September 2018 AS3500.4

Chlorine dioxide as disinfectant warning

HWRS Copper Chlorine Flow Chart

Please only use the aquatherm proprietary pipe clamps!

Welding procedures videos:

![]()

20-63mm: Socket Fusion

50-125mm: Socket Fusion

160mm and up: Butt welding

20-250mm: Electrofusion

Available dimensions:

|

Art-No. |

Dimension |

DN |

|

70758 |

20 x 2.8 mm |

15 |

|

70760 |

25 x 3.5 mm |

20 |

|

70762 |

32 x 4.4 mm |

25 |

|

70764 |

40 x 5.5 mm |

32 |

|

70766 |

50 x 6.9 mm |

40 |

|

70768 |

63 x 8.6 mm |

50 |

|

70770 |

75 x 10.3 mm |

50 |

|

70772 |

90 x 12.3 mm |

65 |

|

70774 |

110 x 15.1 mm |

80 |

|

70776 |

125 x 17.1 mm - |

100 |

|

70780 |

160 x 21.9 mm |

125 |

|

70784 |

200 x 27.4 mm |

150 |

|

70788 |

250 x 34.2 mm |

175 |

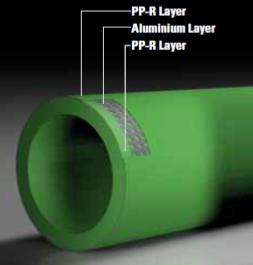

"Old" aquatherm green pipe MS ("Stabi")

In some buildings you can still find the "old" aquatherm green pipe MS ("Stabi"). The "Stabi" pipe is mechanically stabilized through an integrated aluminium layer. The "Stabi" pipe can be recognized by the "golf ball" like indentations on the outside of the pipe.

By using the standard aquatherm green fittings you can connect any aquatherm green pipe to the old "Stabi" pipe.

Peeling of the Aluminium layer

When welding "Stabi" pipe peel off the Aluminium layer off the aquatherm green pipe MS ("Stabi") before fusion.

Push the end of the "Stabi" pipe into the guide of the peeling tool. Peel off the Aluminium layer up to the top of the peeling tool. It is not necessary to mark the welding depth as the back stop of the peeling tool indicates the correct welding depth.

Before starting the fusion, check if the Aluminium layer has been completely removed.

NEW Universal peeling tools for "Stabi", UV and OT pipes

Click here for more information on the universal pipe peelers for the "Stabi" pipe

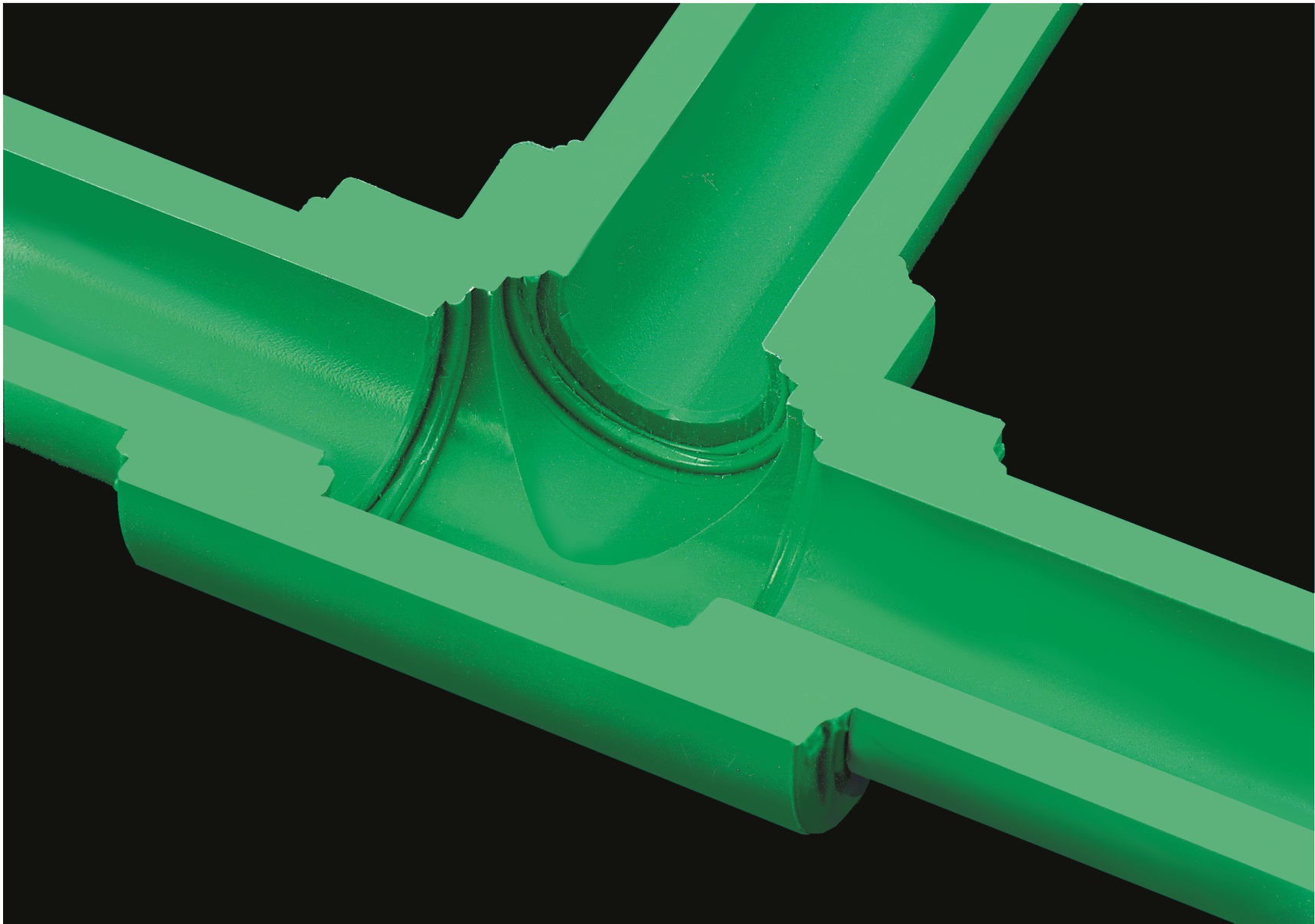

Shipbuilding

Shipbuilding

After its success ashore, aquatherm green pipe increasingly manages to get hold of the sanitary sector in international shipbuilding.

Beside of its corrosion resistance and easy processing, even at sea, the vibration stable PP-R system convinces through its safe connection technique.

The aquatherm green pipe system complies with the requirements of the fire classification

B2 DIN 4102 (normal inflammable).

Compared to natural products like wood, cork or wool, aquatherm green pipes do not produce any gas toxicity.

There is no risk of dioxin emission, which is especially important with liners.

Numerous registrations, certificates and test results confirm:

aquatherm green pipe - the optimum system for shipbuilding!

International certificates

For more information, click here to download the aquatherm shipbuilding brochure

For more information, click here to download the aquatherm green pipe brochure